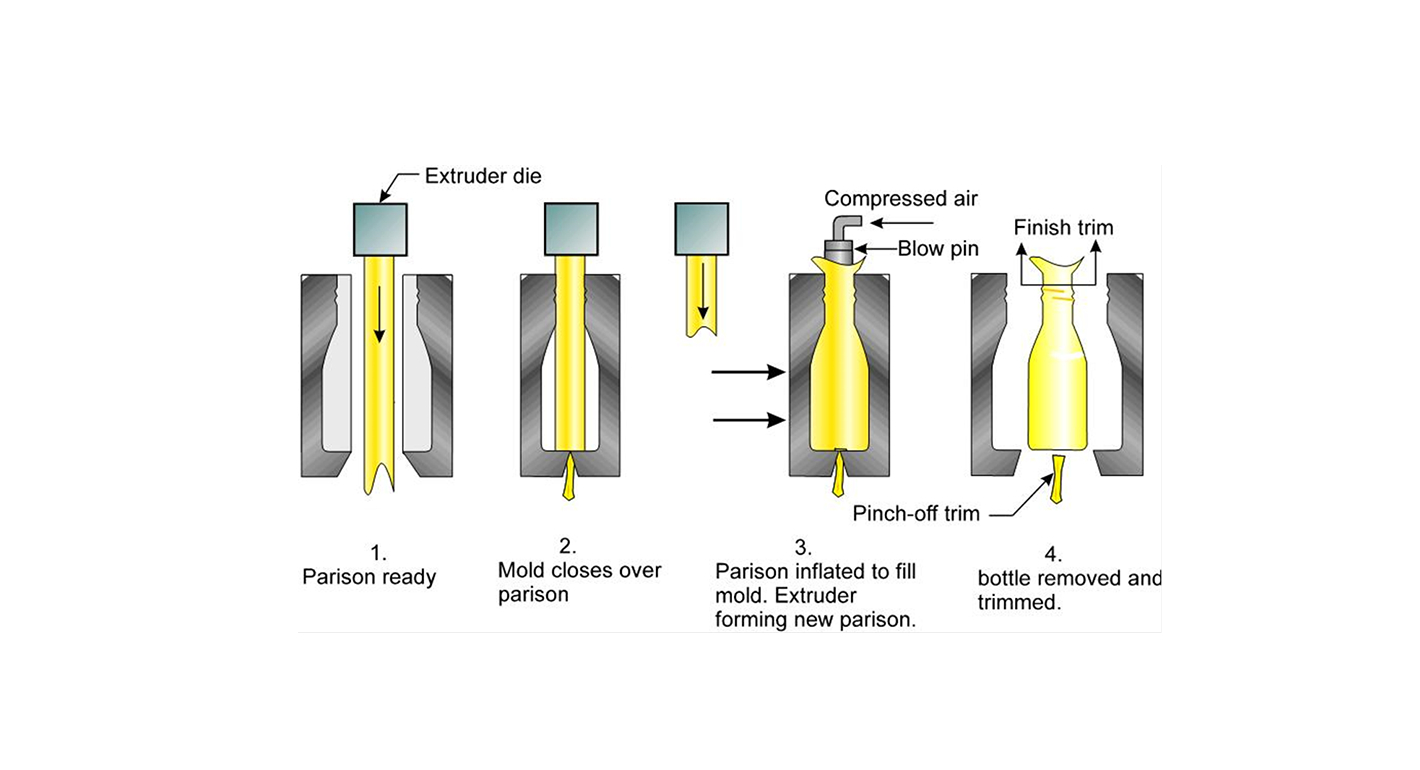

Designing molds for complex part geometries presents unique challenges that require careful consideration and strategic solutions. First and foremost, a detailed analysis of the intricate part geometry is essential. This involves assessing features like undercuts, varying wall thicknesses, and complex curves that may pose challenges during the molding process.

Incorporating Advance Features

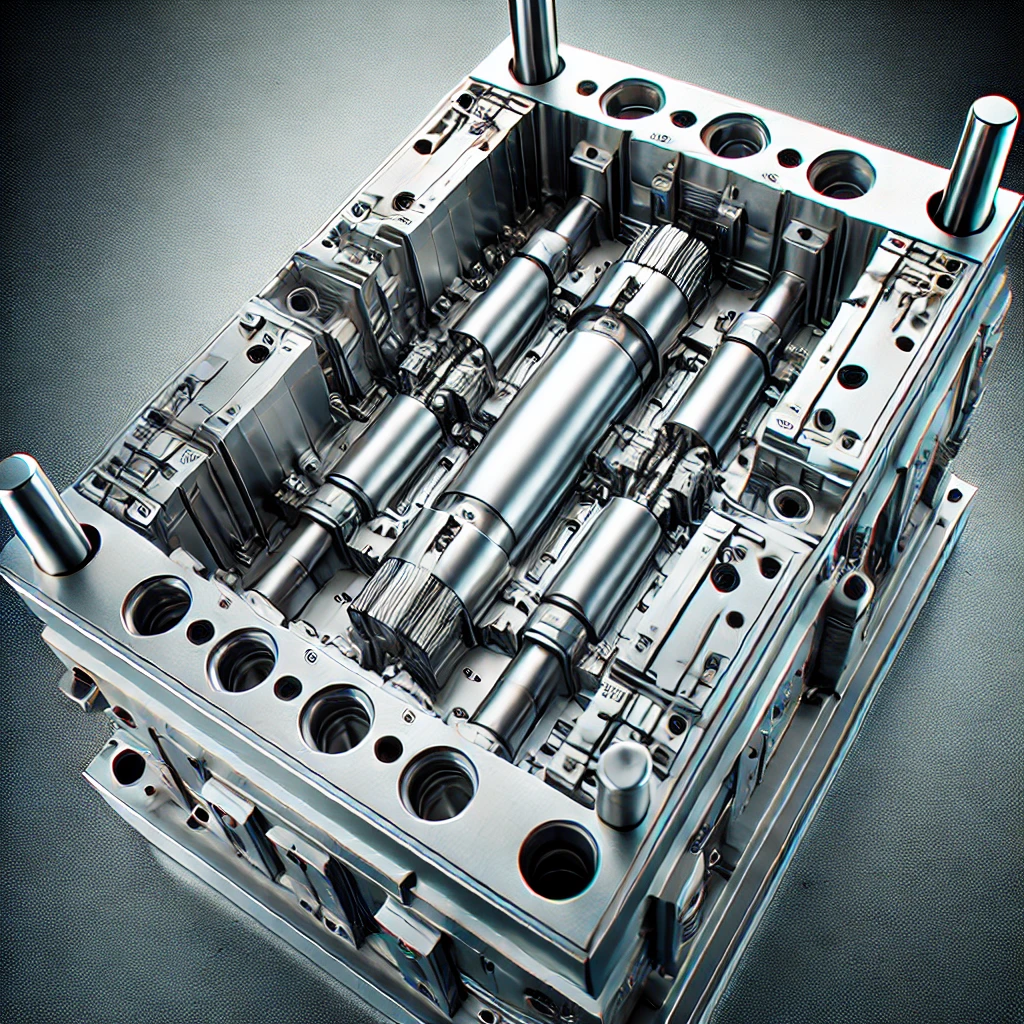

To address these challenges, the incorporation of advanced mold features becomes crucial. The use of side cores, slides, or lifters allows for the creation of undercuts and intricate details in the molded parts. These features move within the mold during the ejection phase, enabling the production of complex geometries that might otherwise be challenging to achieve.

Collaborating With Part Designer

Furthermore, close collaboration between mold designers and part designers is key. This collaborative approach ensures that the mold design aligns seamlessly with the intended part geometry. Regular communication helps identify potential issues early in the design process, allowing for efficient problem-solving and optimization.

Selecting The Right Materials

The selection of appropriate materials for the mold also plays a pivotal role in overcoming challenges associated with complex part geometries. High-quality tool steels or advanced materials with excellent wear resistance may be necessary to withstand the demands of molding intricate shapes repeatedly.

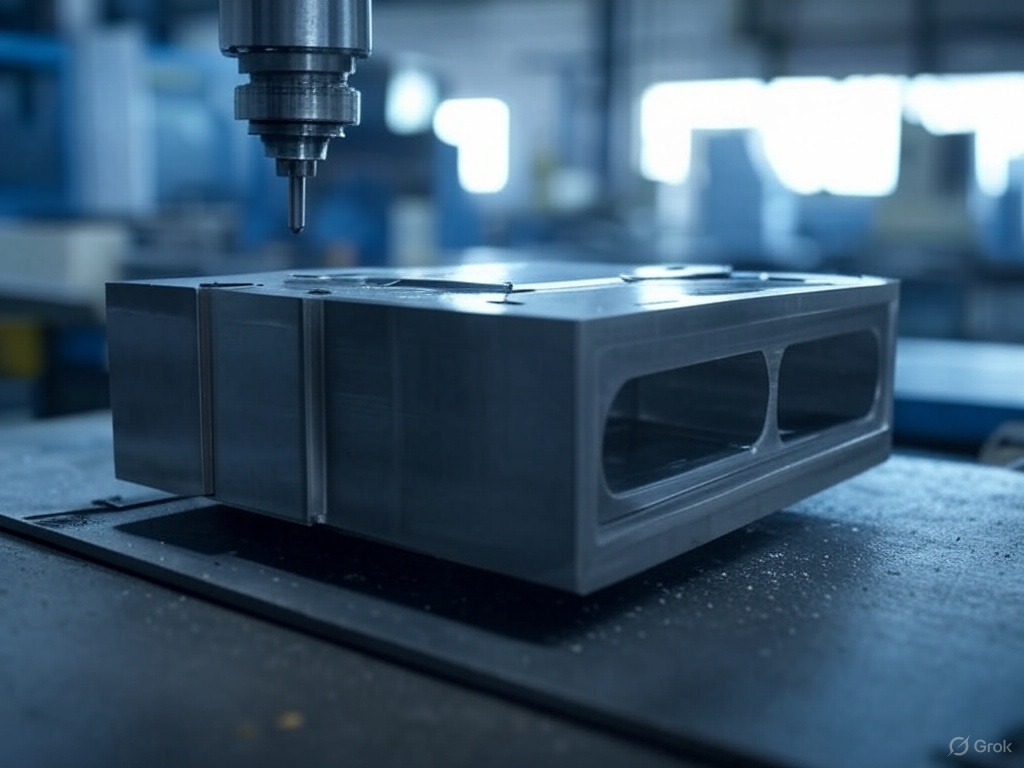

Moreover, the use of advanced technologies, such as computer-aided design (CAD) and mold flow analysis, aids in simulating the molding process. These simulations help identify potential challenges and optimize the mold design before physical production begins, reducing the likelihood of costly errors and modifications.

In conclusion, addressing the challenges of designing molds for complex part geometries involves a multi-faceted approach. This includes in-depth analysis of part geometry, incorporation of advanced mold features, collaboration between design teams, careful material selection, and the utilization of advanced technologies for simulation and optimization. This comprehensive strategy ensures the successful production of high-quality parts with intricate geometries.