Blow molding, a widely employed manufacturing process for hollow plastic parts like bottles and containers, encompasses various techniques. Among these, injection blow molding and extrusion blow molding are prominent. This discussion will delve into the intricacies of each method, emphasizing the advantages of injection blow molding(IBM) over extrusion blow molding(EBM).

1. Injection Blow Molding: Process Overview

1.1. Injection Phase

To initiate the process, thermoplastic material undergoes melting and injection into a preform mold, crafting a parison—a tube-like precursor to the final product.

1.2. Blow Molding Phase

Transitioning to the blow molding phase, the parison moves to a blow mold. Here, compressed air enters the scene, expanding the material against the mold walls and precisely shaping it into the desired form. This intricate process ensures uniform product dimensions.

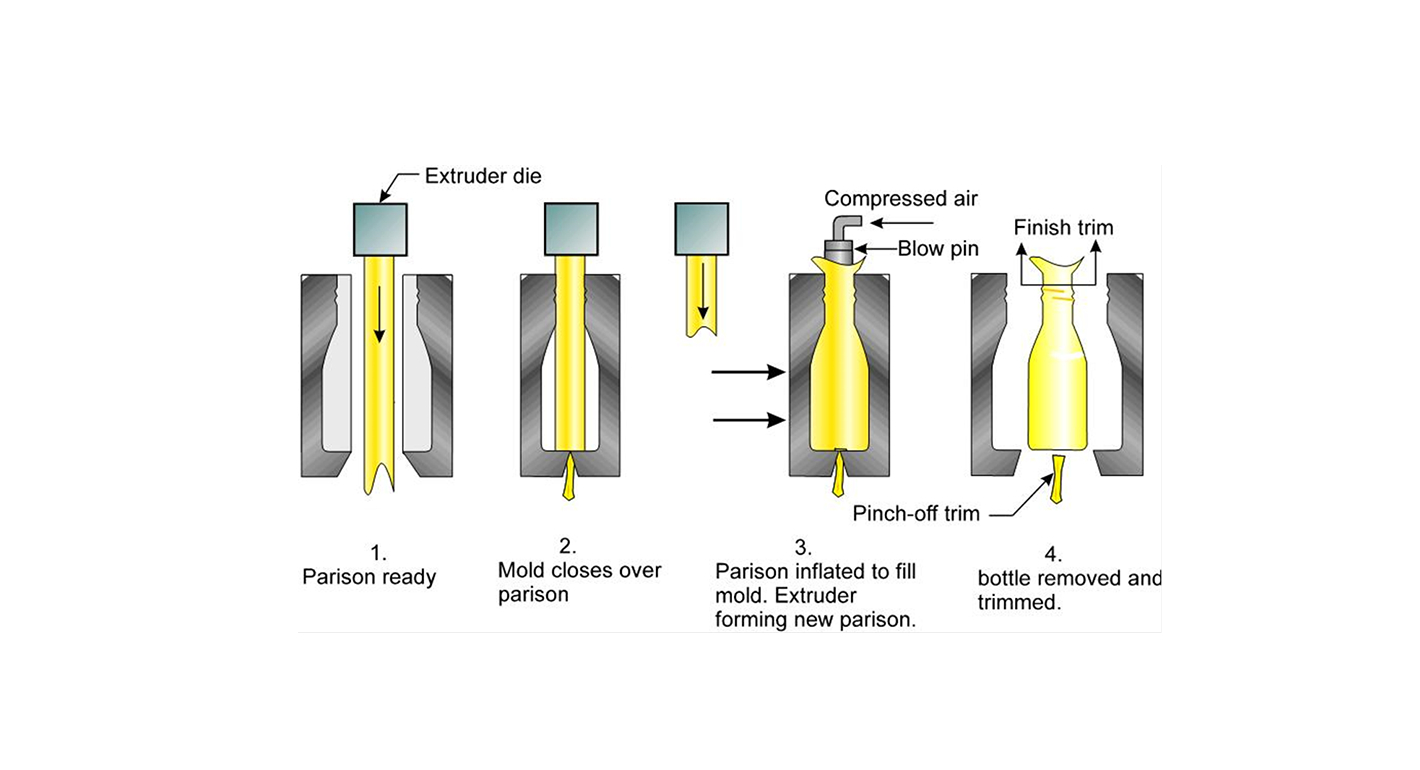

2. Extrusion Blow Molding: Process Overview

2.1. Extrusion Phase

Contrasting with injection blow molding, extrusion blow molding kicks off with the continuous extrusion of a molten tube, or parison, from an extruder. This parison is then enveloped within a mold cavity.

2.2. Blow Molding Phase

Mirroring the injection blow molding’s blow molding phase, extrusion involves introducing compressed air to inflate the parison against the mold walls, resulting in the final product. Nevertheless, this process may induce variations in wall thickness.

3. Advantages of IBM Over EBM

3.1. Greater Precision and Control

A paramount advantage of injection blow molding lies in its ability to achieve superior precision and control over product dimensions. The injection phase facilitates meticulous material distribution, ensuring consistent wall thickness and impeccable product quality.

3.2. Enhanced Surface Finish

Notably, injection blow molding frequently produces products boasting a smoother and more aesthetically pleasing surface finish. This is attributed to the controlled injection of material, reducing the occurrence of imperfections like streaks or seams—commonly encountered in extrusion blow-molded products.

3.3. Reduced Material Waste

One compelling aspect of injection blow molding is its propensity to generate less material waste compared to extrusion blow molding. The controlled injection and shaping of the parison contribute to optimized material usage, rendering it a more sustainable and cost-effective option.

3.4. Versatility in Design

Moreover, injection blow molding stands out for its unparalleled design flexibility, particularly when intricate shapes or complex geometries are prerequisites. The injection phase facilitates the creation of detailed preforms, unlocking possibilities for diverse and innovative product designs.

Conclusion: Choosing the Right Method for Your Needs

In conclusion, while both injection blow molding and extrusion blow molding are integral to plastic manufacturing, the former distinguishes itself through precision, enhanced surface finish, reduced material waste, and design versatility. Profound comprehension of project-specific requirements is pivotal in selecting the most appropriate blow molding method for achieving optimal and customized results.

VolksMolds is a seasoned expert in plastic mold making and product molding. Known for precision and innovation, VolksMolds consistently delivers high-quality solutions tailored to modern needs of packaging, household plastic appliances, and retail display tools.