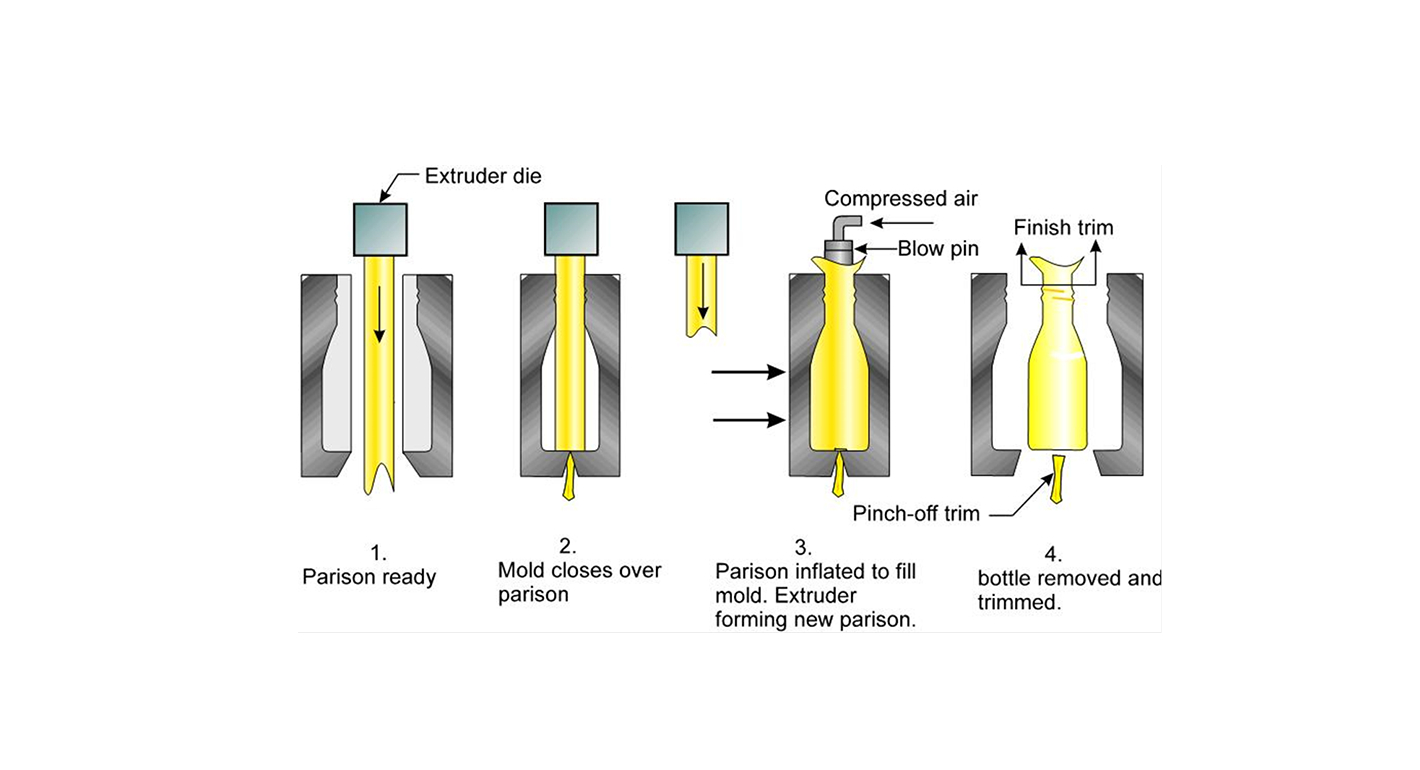

Selecting the right mold materials is a critical aspect of injection molding, directly impacting performance and longevity. This process involves careful consideration of various factors to ensure optimal results.

Influence of Plastic Resin on Material Selection

The type of plastic resin used is a primary guiding factor in material selection. Different resins exhibit varying corrosiveness and abrasiveness, influencing the choice of materials. For high-volume production, durable materials like P20 or H13 tool steels are favored for their exceptional hardness and wear resistance.

Key Role of Thermal Conductivity

Thermal conductivity is a pivotal consideration in maintaining consistent temperatures during the molding process. Materials with high thermal conductivity, such as beryllium copper, effectively dissipate heat. This not only minimizes cycle times but also enhances overall productivity.

Surface Finish Preferences and Materials Decision

Desired surface finishes for molded parts play a crucial role in guiding material decisions. Stainless steel molds are preferred when polished finishes are required, whereas aluminum molds excel in delivering textured or matte finishes.

Balancing Cost and Durability

Economic considerations are integral to the decision-making process. High-grade tool steels, while offering durability, often come with higher upfront costs. In scenarios with lower production volumes or stringent budget constraints, aluminum molds emerge as a more cost-effective choice.

Comprehensive Assessment for Informed Choices

In summary, selecting the right mold materials requires a comprehensive assessment of various factors. These include plastic resin properties, production volume requirements, thermal conductivity needs, surface finish preferences, and budget considerations. This meticulous evaluation ensures that the chosen material precisely aligns with the demands of the injection molding project, promoting efficient and cost-effective production processes.

VolksMolds is a seasoned expert in plastic mold making and product molding. Known for precision and innovation, VolksMolds consistently delivers high-quality solutions tailored to modern needs of packaging, household plastic appliances, and retail display tools.