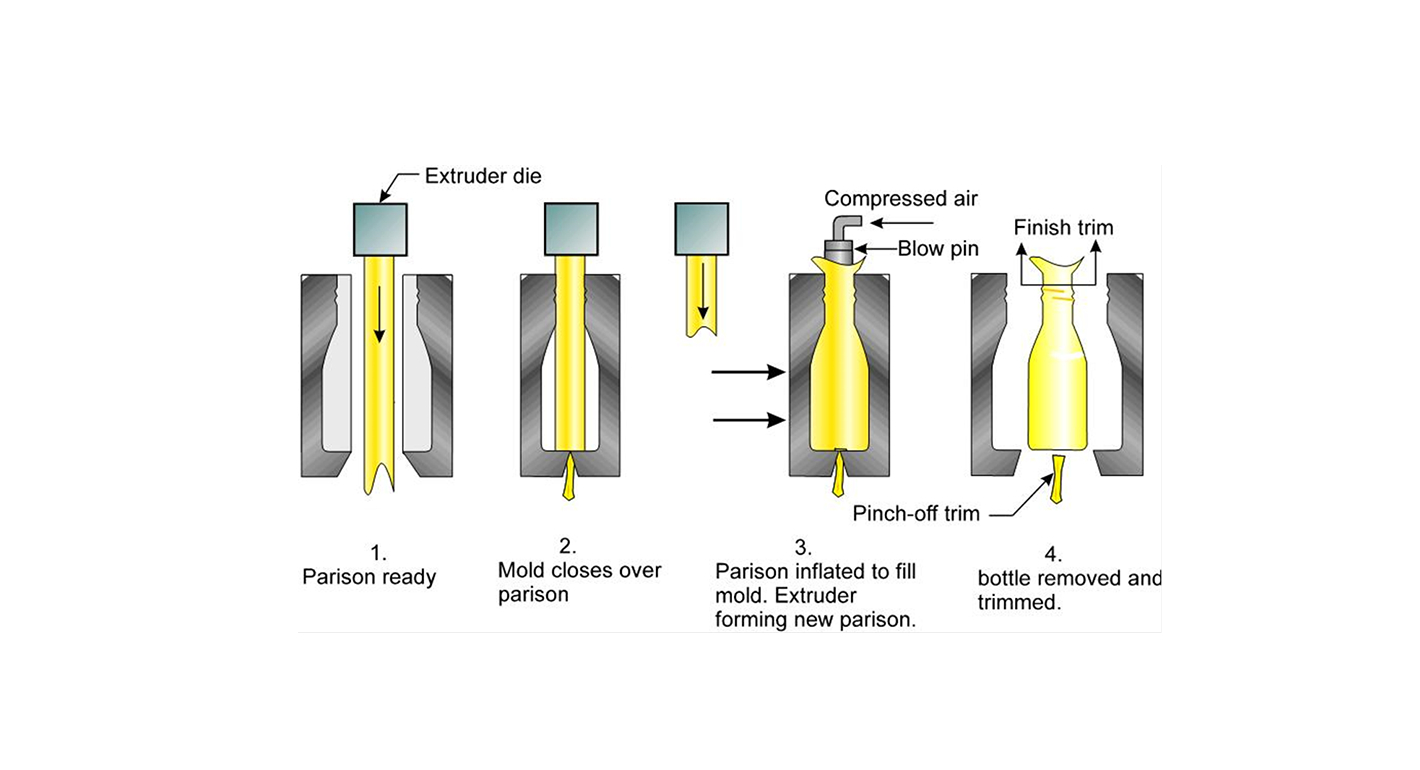

Injection mold gates are openings through which molten plastic is introduced into the mold cavity. The choice of injection mold gating types can affect the quality, appearance, and efficiency of the injection molding process. There are several common types of injection mold gates:

Injection mold gating types

- Sprue Gate:

- Located at the entry point of the mold.

- Connects the nozzle of the injection molding machine to the runner system.

- Particularly effective in larger parts and molds.

- Runner Gate:

- Distributes the plastic material from the sprue to the individual cavities.

- Various types include:

- Cold Runner: The plastic remains in the runner and solidifies after each shot.

- Hot Runner: The runner system is heated, allowing the plastic to remain molten and reducing waste.

- Edge Gate:

- Positioned at the edge of the part.

- Commonly used in flat or thin-walled parts.

- May leave a small scar on the part.

- Submarine Gate:

- Similar to an edge gate but positioned beneath the part’s surface.

- Aims to reduce visible gate marks on the final part.

- Tab Gate (Fan Gate):

- Suited for flat or thin parts.

- The gate has a tab-like shape that is easy to remove.

- Leaves a small scar on the part.

- Pinpoint Gate (Direct Gate):

- Features a small-diameter gate located directly at the part surface.

- Results in a minimal gate mark, particularly suitable for aesthetic parts.

- Tunnel Gate:

- A small tunnel-like gate leading into the part.

- Commonly employed in cosmetic parts to conceal the gate mark.

- Cashew Gate (Banana Gate):

- Resembling the shape of a cashew or banana.

- Applied in aesthetic parts to minimize gate marks.

- Film Gate:

- Features a very small gate to reduce the visibility of the gate mark.

- Suited for thin-walled parts.

- Fan Gate:

- Distributes the plastic into the cavity in a fan-shaped pattern.

- Helps control flow and minimizes the likelihood of visible gate marks.

The choice of gate type depends on factors such as the part design, material properties, cosmetic requirements, and the molding process. Different gates have their advantages and limitations, and selecting the appropriate gate type is crucial for achieving the desired results in injection molding.