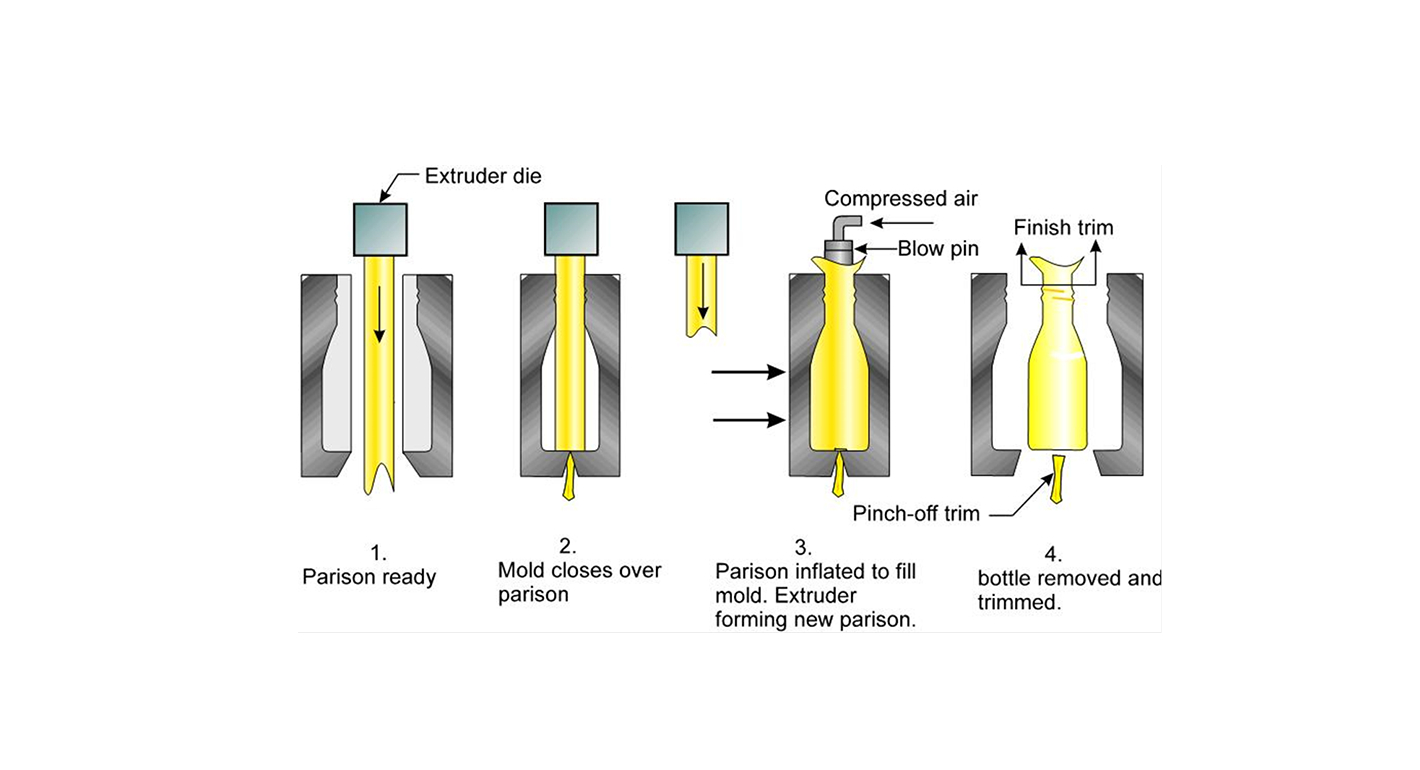

The plastic molds and molded parts industry operates in a dynamic environment where adherence to regulations and standards is critical. These guidelines ensure the production of high-quality, safe, and compliant products. This article provides an overview of some of the common plastic molds and parts regulations and standards shaping the industry, covering aspects from quality management to environmental responsibility.

I. SPI Standards: A Cornerstone in Plastics Manufacturing

Society of the Plastics Industry (SPI) standards play a pivotal role in the plastics industry, providing a standardized framework for manufacturing processes. The SPI Resin Identification Code, a prominent element of these standards, allows for efficient sorting and recycling of plastics, contributing to sustainable practices. Additionally, SPI mold classification standards facilitate clear communication between molders and moldmakers, streamlining the production process.

II. ASTM D618: Conditioning Plastics for Robust Testing

ASTM D618 sets standards for conditioning plastics before testing, ensuring uniformity in testing conditions. This is crucial in the plastic molds and molded parts industry, where reliable and comparable test results are imperative for quality assurance.

III. ISO 13485: Elevating Quality in Medical Device Manufacturing

ISO 13485 stands as a beacon for organizations involved in the design, production, and servicing of medical devices. With a focus on risk management, this international standard ensures that potential issues are proactively addressed throughout the product lifecycle. ISO 13485 compliance is not only a regulatory requirement but also a strategic move that instills confidence in customers, regulators, and stakeholders, emphasizing a commitment to quality and safety.

IV. RoHS Directive: Mitigating Hazardous Substances

The Restriction of Hazardous Substances (RoHS) Directive restricts the use of hazardous substances in electrical and electronic equipment, including plastic components. Compliance is essential for manufacturers, especially when exporting to the European Union, to ensure products align with health and environmental safety standards.

V. REACH Regulation: Safeguarding Chemical Usage

The REACH Regulation in the European Union governs chemical substances used in plastic molds and molded parts. Its focus on human health and environmental safety underscores the industry’s commitment to responsible chemical usage.

VI. FDA Regulations: Ensuring Safety in Food Contact

For plastic molds and molded parts destined for food-related applications, compliance with FDA regulations is imperative. These regulations, set by the U.S. Food and Drug Administration, ensure the safety of materials in contact with food, protecting consumers.

VII. UL Standards: Upholding Safety in Plastics

Underwriters Laboratories (UL) develops safety standards for various products, including plastics. Covering aspects such as flammability and electrical properties, UL standards contribute to meeting rigorous safety requirements in the plastic industry.

VIII. ANSI/PLASTICS B151.1: Safety in Machinery Operation

Developed by the Plastics Industry Association, ANSI/PLASTICS B151.1 focuses on safety requirements for plastics machinery. It addresses crucial aspects like safeguarding, maintenance, and operational procedures, ensuring a secure manufacturing environment.

IX. OSHA Standards: Prioritizing Workplace Safety

Occupational Safety and Health Administration (OSHA) standards play a pivotal role in ensuring workplace safety within the plastic molds and molded parts industry. Covering areas like machine guarding and hazard communication, these standards contribute to the well-being of workers.

X. IEC 61215: Guiding Solar Panel Component Production

For manufacturers involved in molded parts for solar panels, compliance with IEC 61215 is essential. This standard outlines design qualification and type approval requirements for crystalline silicon terrestrial photovoltaic modules, ensuring reliability and safety.

In conclusion, the plastic molds and molded parts industry navigates a complex landscape of regulations and standards, each serving a crucial role in ensuring product quality, safety, and environmental responsibility. From SPI standards that standardize manufacturing processes to ISO 13485, emphasizing quality in medical device manufacturing, compliance with these guidelines is not just a legal requirement but a strategic imperative. Manufacturers that embrace and exceed these standards position themselves as leaders in an industry that demands precision, reliability, and a commitment to excellence. Staying informed and proactive in compliance is the key to sustained success in this ever-evolving sector.

VolksMolds is a seasoned expert in plastic mold making and product molding. Known for precision and innovation, VolksMolds consistently delivers high-quality solutions tailored to modern needs of packaging, household plastic appliances, and retail display tools.