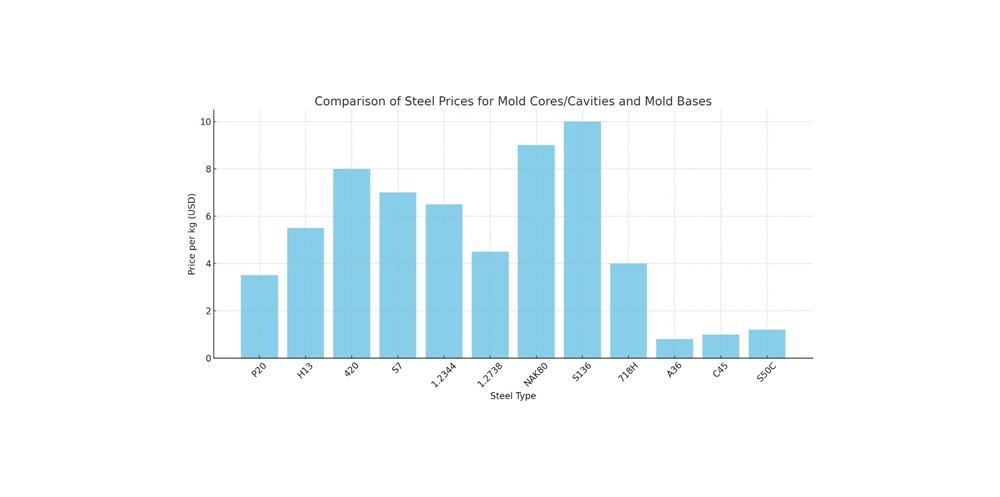

The above is an bar chart comparing the mold steel costs per kilogram for both core/cavity and base. The prices provided are illustrative and actual costs may vary based on market conditions, suppliers, and specific material grades.

Comparison of Steel Prices (USD per kg)

Base Steels

-A36: $0.8

-C45: $1.0

-S50C: $1.2

Core and Cavity Steels

-P20: $3.5

-718H (P20+Ni): $4.0

-1.2738 (P20+Ni): $4.5

-H13: $5.5

-1.2344 (H13): $6.5

-S7: $7.0

– 420 Stainless Steel: $8.0

-NAK80: $9.0

-S136: $10.0

Analysis of mold steel costs

-Cheapest Mold Base Steels: A36, C45, and S50C, making them cost-effective for constructing mold bases where high strength is not a primary requirement.

-Mid-range Steels: 1.2738 and 718H offer a balance of cost and performance for both core/cavity and base applications.

-More Expensive Steels: H13, 1.2344, and S7 are chosen for their enhanced properties in more demanding applications.

-Most Expensive Steels: 420, NAK80, and S136, used for specialized molds requiring superior corrosion resistance and polishability.

Selecting the appropriate steel type involves considering performance needs, production volume, and budget constraints. The properties of each steel type make them suitable for different applications in the mold-making process.