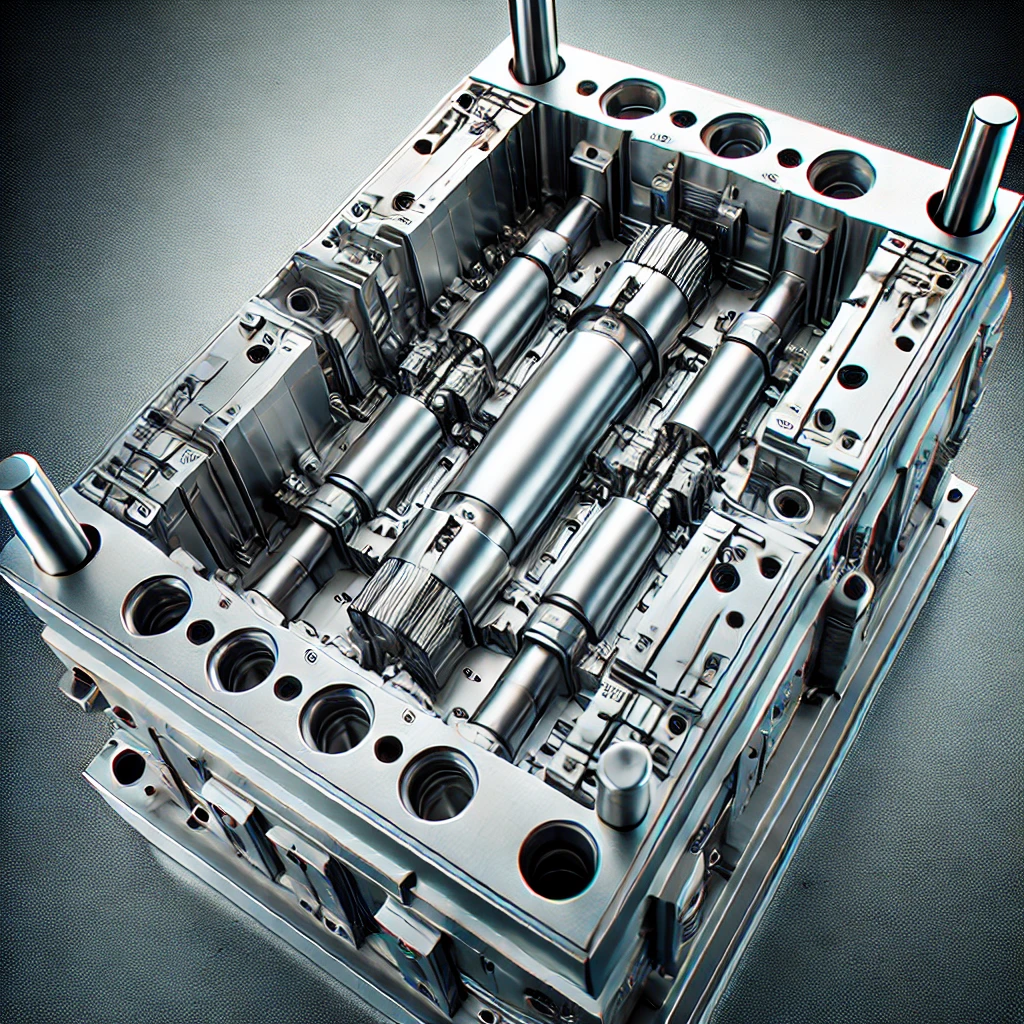

In the plastic molding industry, manufacturers commonly use different types of mold steel for cores/cavities and bases. They select each type based on its specific properties and performance characteristics. Here’s a breakdown:

Types Of Mold Steel For Core & Cavity

| Type | Property | Usage | |

| 1 | P20 | Pre-hardened, around 30-35 HRC. Good machinability and polishability. | Common for general-purpose molds, including those for moderate production volumes. |

| 2 | H13 | Can be hardened up to 50-54 HRC. Excellent toughness, heat resistance, and wear resistance. | Suitable for high-pressure molding and molds that require high wear resistance. |

| 3 | 420 stainless | Can be hardened up to 50-55 HRC. Good corrosion resistance and polishability | Ideal for molds used with corrosive materials or environments, such as PVC or for producing optical parts. |

| 4 | S7 | Can be hardened to around 54-58 HRC. High toughness and shock resistance | For molds where high impact and toughness are critical, such as for molding heavy or abrasive materials. |

| 5 | 1.2344 (H13) | Hot work tool steel, excellent toughness, heat resistance, and wear resistance. Can be hardened to around 50-54 HRC | Suitable for high-pressure and high-temperature molding applications. |

| 6 | 1.2738 (P20+Ni) | Modified version of P20, better toughness and uniform hardness. Pre-hardened to around 30-36 HRC | For larger molds requiring uniform hardness, such as automotive and home appliance parts. |

| 7 | NAK80 | Pre-hardened, 40 HRC. Excellent machinability, polishability, and corrosion resistance | Ideal for high-precision molds, including those for cosmetic and electronic parts. |

| 8 | S136 | Can be hardened to around 50-52 HRC. Excellent corrosion resistance, high polishability, and wear resistance | Used for molds that require high corrosion resistance and a mirror finish, such as for medical and optical parts. |

| 9 | 718H | Pre-hardened, 33-37 HRC. Similar to 1.2738 with added nickel for improved toughness | Commonly good for medium to large-sized molds with uniform hardness requirements. |

Types Of Mold Steel For Mold Base

| Type | Property | Usage | |

| 1 | P20 | Pre-hardened, 30-35 HRC. Good machinability | Common for mold bases, similar to its use in cores and cavities for moderate production |

| 2 | A36 | Lower carbon steel, typically not hardened. Good weldability and machinability | Often used for the construction of mold bases due to its cost-effectiveness and ease of fabrication |

| 3 | C45(1045) | Medium carbon steel, can be hardened and tempered | Used for mold bases where more strength and hardness are needed compared to lower carbon steels |

| 4 | S50C | Medium carbon steel, similar to C45. Can be hardened | Another option for mold bases, providing a balance of strength and machinability. |

Factors Influencing Steel Selection

- Production Volume: Higher volumes require more durable, wear-resistant steels.

- Resin Material: Use specialized steel if materials are corrosive or abrasive.

- Mold Design: Complex designs might benefit from steels with better machinability and polishability.

- Cost Considerations: Balancing performance requirements with material cost.

Each of these steel types offers specific advantages, ensuring durability, performance, and cost-effectiveness tailored to the specific requirements of the molding process.